Why Safe Access to Drift Eliminators Matters

It’s surprisingly common for cooling towers to lack a safe and practical way to reach the drift eliminators. Whether it’s missing ladders, corroded walkways or poor tower placement, restricted access doesn’t just make scheduled cleans more difficult — it can directly impact compliance, performance, and safety.

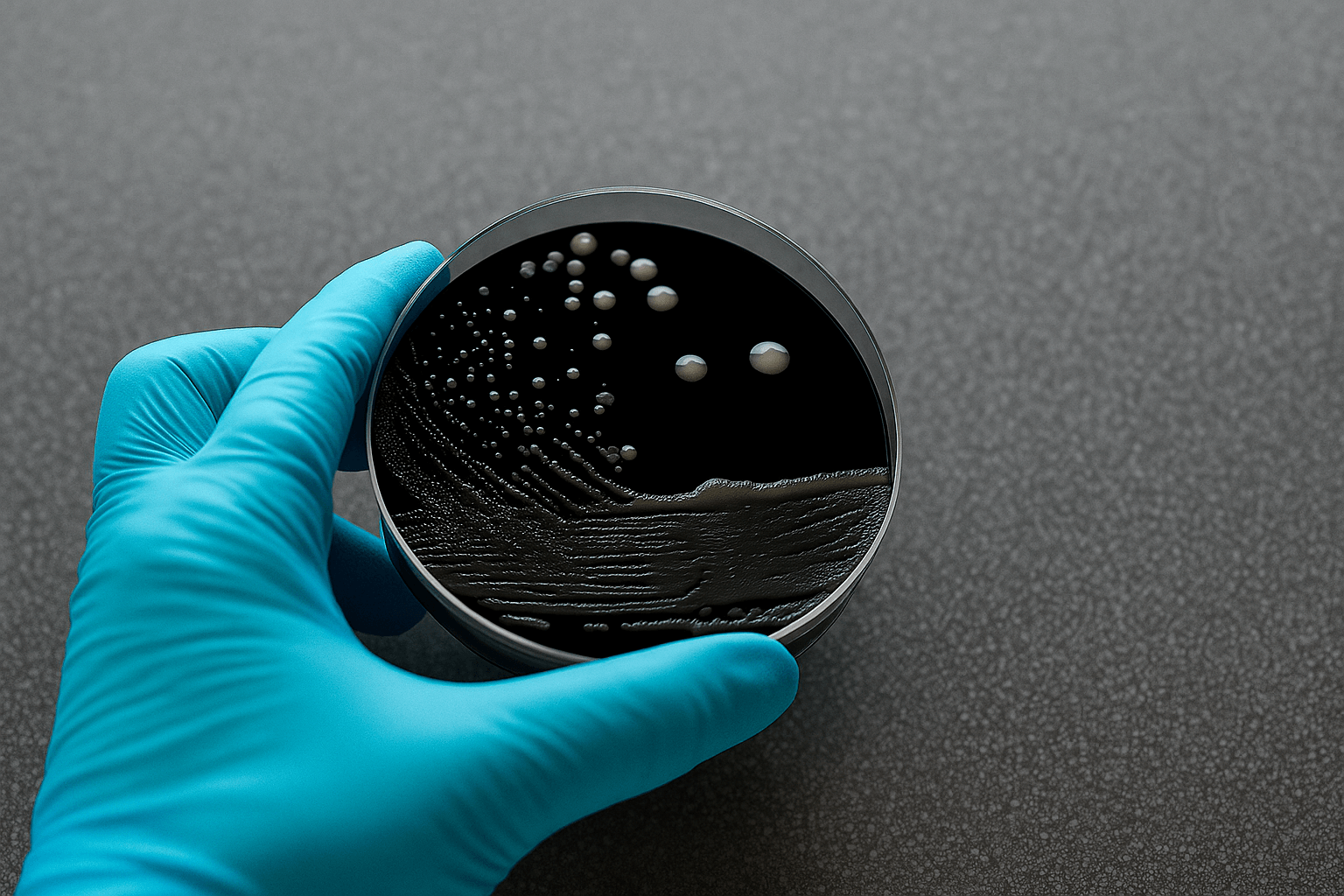

During a cooling tower clean, technicians must inspect and clean the drift eliminators. This step is essential to ensure the eliminators remain free of scale, corrosion, and biofilm, allowing them to capture water droplets and minimise the risk of Legionella. When safe access is unavailable, cleaners can’t complete this inspection, leaving the site exposed to both mechanical and compliance risks.

Under Victoria’s Public Health and Wellbeing Regulations 2019 and associated Risk Management Plan (RMP) requirements, drift eliminators must be inspected and maintained during each scheduled tower clean. These inspections are a non-negotiable compliance task because they directly influence Legionella control and system safety. If cleaners cannot safely reach the eliminators, they cannot inspect or verify their condition. Over time, this can result in incomplete records, repeated non-compliance findings, and even the potential for an RMP audit failure. The Department of Health expects that all components of the cooling tower system — including eliminators — can be accessed safely for inspection and cleaning.

Repeated findings of “inadequate access” may require notification to the local health authority or lead to a direction for rectification under the Act. In practice, the absence of safe access is often identified as a systemic issue that must be addressed through engineering modification, rather than administrative workaround.

The Practical Impact of Poor Access

When eliminators can’t be reached safely, cleaning teams may need to bring in scaffolding or elevated work platforms, significantly increasing time and cost. In some cases, they may not be able to proceed with the inspection at all — leaving the site without evidence that the eliminators were checked. Without proper access:

- Biofilm, debris and scale can accumulate in the eliminator packs, restricting airflow and allowing drift to escape.

- Chemical efficiency drops as water losses increase.

- Microbiological risk rises, as untreated surfaces provide a growth point for bacteria.

- The facility’s RMP audit trail weakens, as inspections are logged as “unable to access.”

These issues rarely remain isolated; they usually appear together — reduced efficiency, increased risk, and an eventual audit non-conformance.

Designing for Safe and Efficient Access

Creating or improving access to drift eliminators doesn’t need to be complicated. Many sites can achieve compliance simply by adding engineered access points or refurbishing existing ladders and platforms. Safe access generally includes:

- A fixed ladder or stair system providing direct entry to the eliminator deck.

- Secure handrails and guardrails to prevent falls.

- Non-slip walkways that allow cleaners to move safely across the top of the tower.

- Hinged or removable hatches positioned for direct access to eliminator panels.

- Clear access zones free from pipework or obstructions.

Where these features are missing, they can often be retrofitted without major disruption. The result is safer working conditions, reduced cleaning time, and a consistent compliance record during audits.

Tandex technicians assess cooling tower access as part of regular water treatment visits and service reviews. If the team identifies unsafe or impractical access to drift eliminators, this is clearly documented and discussed with the site’s maintenance representative. The goal is always prevention — helping customers address physical access barriers before they result in non-compliance or a failed audit. By maintaining strong communication between service technicians, tower cleaners, and site management, these issues can usually be resolved through straightforward engineering solutions.

For sites without safe access to drift eliminators, the path to compliance is straightforward. Taking the following steps ensures maintenance can be performed safely and inspections completed every time:

- Review your cooling towers to confirm whether drift eliminators can be safely reached for inspection and cleaning.

- Engage a qualified engineer or tower manufacturer to design compliant access points if they’re missing.

- Coordinate upgrades with your next scheduled tower clean or refurbishment to minimise downtime.

- Document the changes in your Risk Management Plan and include photos of new access structures for audit evidence.

- Verify compliance by confirming the new access allows cleaners to inspect eliminators safely every time.

Before making any upgrades, it helps to step back and look at what really matters most when it comes to safe access. Here are a few quick takeaways to keep in mind:

Safe access to drift eliminators is more than a maintenance detail — it’s a compliance requirement and a smart investment that pays off every time your tower is serviced. When these components can’t be safely reached, sites face unnecessary safety risks, cleaning complications, and the potential for audit non-conformance. Establishing proper access is straightforward, cost-effective, and essential for long-term system performance. A well-designed access point protects workers, allows cleaners to complete required inspections, and provides the documentation needed for smooth RMP audits.

For advice on creating or improving safe access to drift eliminators, or to discuss options for cooling tower compliance support, contact us today.